Steel Drip Trays

Steel drip trays are made from high quality durable steel material that can withstand being exposed to hazardous substances. We know the importance of having steel drip trays on site. We have a wide range of steel drip trays to help you store and transport your hazardous chemicals and liquids as safely as possible.

Mild Steel Small Drip Tray

Mild Steel Small Drip Tray

Mild Steel Medium Drip Tray

Mild Steel Medium Drip Tray

Mild Steel Long Drip Tray

Mild Steel Long Drip Tray

Mild Steel Large Drip Tray

Mild Steel Large Drip Tray

Mild Steel Medium Drip Pan

Mild Steel Medium Drip Pan

Mild Steel Sqaure Drip Pan

Mild Steel Sqaure Drip Pan

Mild Steel Long Drip Pan

Mild Steel Long Drip Pan

Mild Steel Large Drip Pan

Mild Steel Large Drip Pan

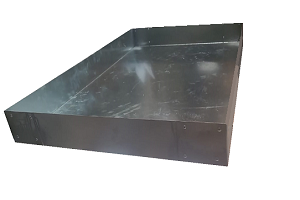

Galvanised Steel Drip Tray

Galvanised Steel Drip Tray

Why choose steel drip trays?

Drips and spillages are common occurrences on building sites and in other industrial working environments therefore, our drip trays serve as effective solutions for capturing these leaks before they pose a hazard. These versatile spillage trays can accommodate a variety of drums or containers, whether placed under machinery, vehicles, or larger equipment like generators. Our drip trays are made from high-quality steel and our drip trays are durable and sturdy, capable of withstanding exposure to hazardous substances. We offer customization options to ensure they fit your specific environment and requirements, including features like handles and caster wheelset, therefore you have choices for the design of a steel drip tray that is suitable for your application. Additionally, our galvanized steel trays are designed without welds because galvanised steel does not take well to welding therefore, we have created a design that allows us to manufacture leak proof no weld galvanised trays.

For larger containers, consider our spill decks, which provide a straightforward drainage system after potentially hazardous leaks. You can find our spill decks here.

What are the benefits of using steel drip trays?

Steel drip trays offer several benefits:

- Durability: Steel trays are robust and can withstand heavy use therefore making them suitable for industrial environments, workshops, and on sites

- Chemical Resistance: Stainless steel and galvanized steel are resistant to corrosion and chemical spills. They won’t degrade when exposed to oils, acids, or other substances therefore these are suitable options for outdoor environment with high moisture exposure.

- Easy Maintenance: Steel trays are easy to clean. Simply wipe or rinse them to remove spills, drips, or debris and this in turn will ensure your steel trays last a lot longer.

- Safety: By containing leaks and spills, steel drip trays prevent slippery surfaces and reduce the risk of accidents hence it is important to have the correct products in place to prevent such incidents from occurring.

- Versatility: Steel trays can be used under machinery, vehicles, or as catchment areas for liquids.

Remember to choose the right size and material based on your specific needs!

How do I choose the right size for my needs?

When selecting the right size for your drip tray, consider the following factors:

- Container Size: Measure the dimensions of the containers or equipment you want to place on the tray and ensure the tray is large enough to accommodate them comfortably.

- Available Space: Consider the available space where you’ll place the tray and choose a size that fits within the designated area without causing obstruction.

- Fluid Volume: Estimate the maximum volume of fluid you expect to collect for example, if you’re dealing with small leaks or drips, a smaller tray may suffice and for larger spills, opt for a larger tray.

- Application: Think about the specific application. Is it for a workshop, or industrial setting because different environments may require different tray sizes.

- Safety Margin: It’s a good idea to choose a slightly larger tray than the minimum required as this provides a safety margin in case of unexpected spills.

Remember, the right size ensures effective containment without wasting space.

What is the difference between galvanized and mild steel?

Let’s explore the differences between galvanized steel and mild steel:

- Galvanized Steel:

- Galvanized steel is regular steel that has been coated with a layer of zinc therefore it is more resistant to corrosion than mild steel.

- Suitable for use in corrosive environments, such as outdoor applications or areas with moisture exposure.

- Slightly more expensive due to the zinc coating, but its increased durability justifies the cost.

- Mild Steel:

- Mild steel is untreated steel without any galvanization, and it is softer than galvanized iron but more prone to rusting when exposed to moisture or water over time.

- It is commonly used in various applications but requires protection against corrosion (e.g., paint or coatings). Our mild steel trays have both a rust proof coating and a paint coating which ensures the best protection of your mild steel trays.

In summary, galvanized steel offers better corrosion resistance and durability, while mild steel is more affordable but needs additional protection against rust. Choose based on your specific needs and budget!

What are the alternatives to steel drip trays?

While steel drip trays are commonly used, there are several alternative materials and designs available for spill containment. Let’s explore some options:

- Plastic Drip Trays:

- Constructed from Heavy Duty Polyethylene (LLDPE).

- Useful for various situations.

- Durable but lightweight.

- PVC Easy Store Bunds:

- PVC material versions of plastic drip trays.

- Can be stood on or driven over.

- Portable and easy to store option.

- Absorbent Fabric lined Mats

- Used as an alternative to plastic or metal trays for lining crates and kennels.

- Lightweight, convenient, and easy to clean; lining can be easily replaced.

Remember to choose the material and design that best suits your specific needs!